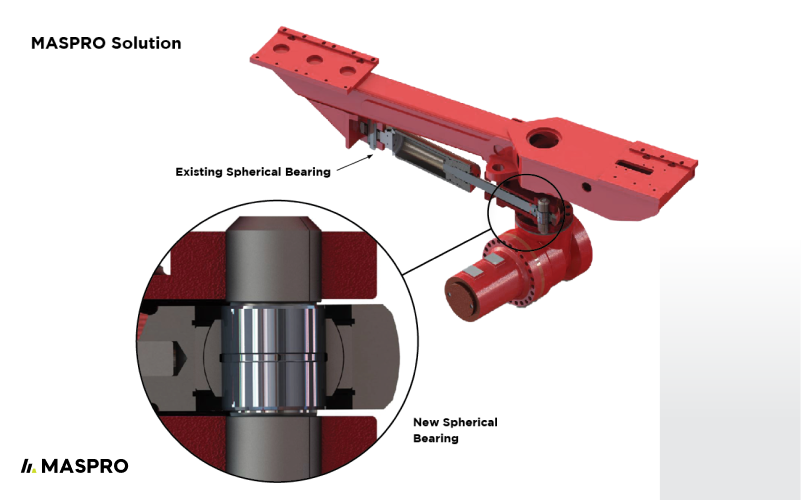

While the Sandvik Axera DD421 two-boom development drill rig is technically designed for drilling tunnels, in Australia and New Zealand (much more so than overseas) it is often used to install rock bolts for ground support, which creates a lot more wear and tear on the boom than may have been intended.

Early failure of original bolting cylinders

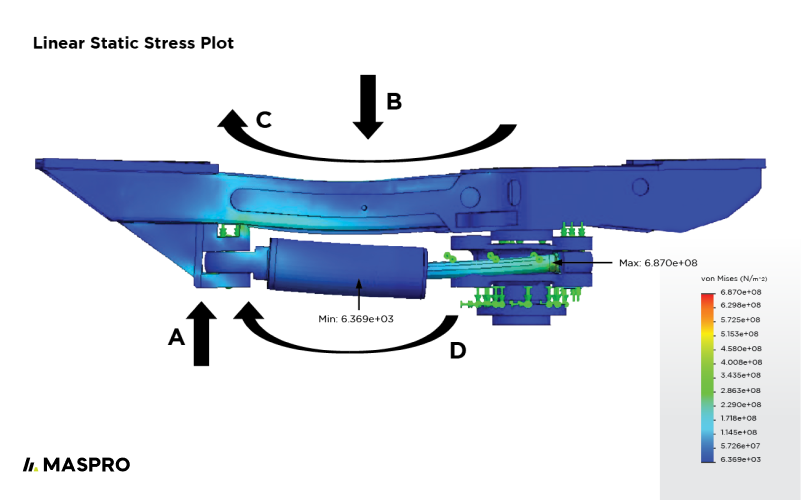

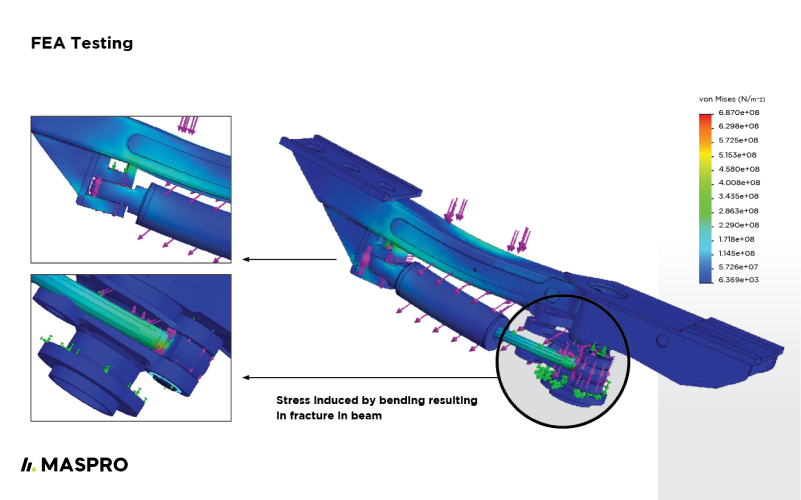

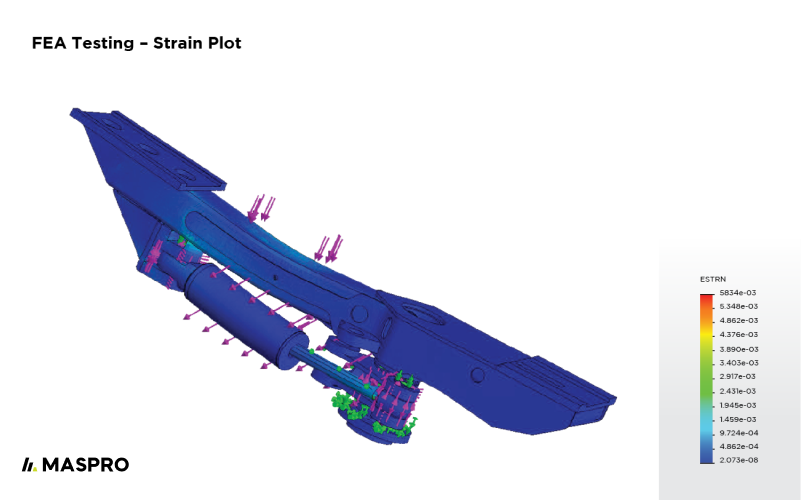

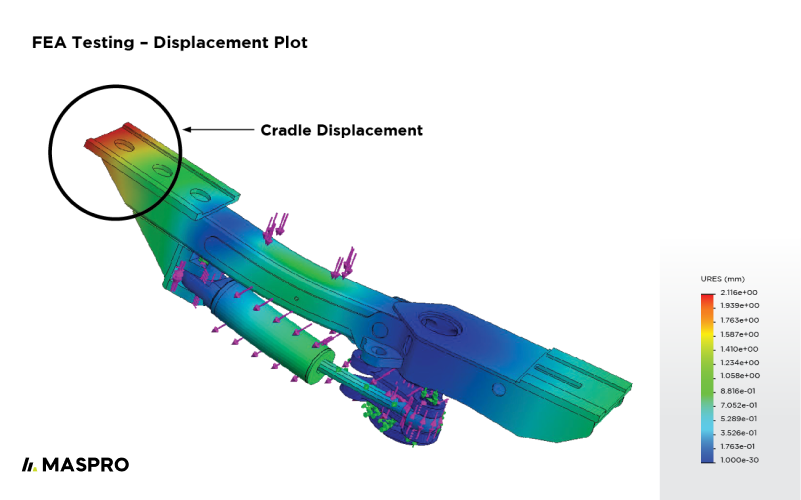

Customers have been reporting the early and frequent failure of original bolting cylinders, coupled with unexplained cracks forming in feed cradles and DPUs that are also forming cracks earlier than would be expected.

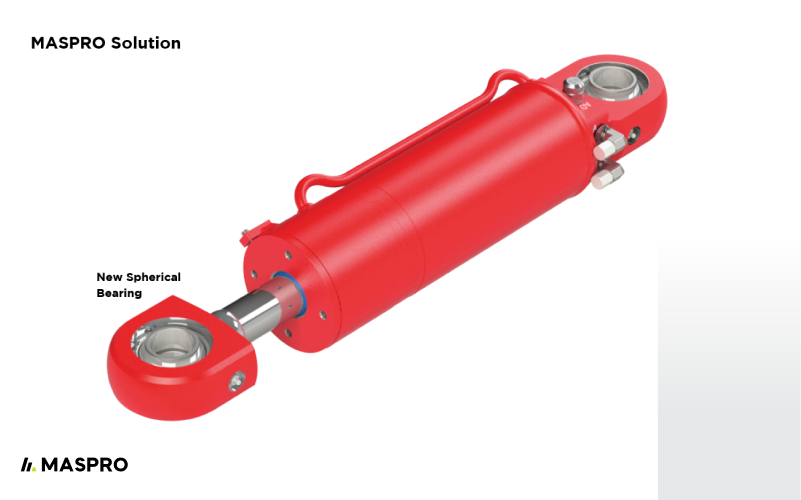

MASPRO has identified the major components that struggle to cope with the demanding task of bolting, and our engineers have redesigned a number of these components used for this demanding operation giving much improved performance.

Even in normal development drilling activities, bolting cylinders face extreme force. After all they are placed in the full extension position during bolting activities which exposes them to bruising from falling debris, corrosion from drill cuttings and harsh UG water, just to name a few.